»Specifications / Parameters

| Parameters | UNIT | EDMN 1060CNC | |

| Working Tank (L x W x H) | mm | 1800 x 1240 x 50 | |

| Max. Oil Level | mm | 350 | |

| Table Size (LxW) | mm | 1380 x 800 | |

| Travel Size | X | mm | 1000 |

| Y | mm | 600 | |

| Spindle Travel(Z) | mm | 400 | |

| Distance between Spindle Nose to Work Table | Min. | mm | 500 |

| Max. | mm | 90 | |

| Max. Table Load (Workpiece weight) | mm | 4000 | |

| Max. Spindle Hold (Electrode weight) | kg | 200 | |

| Oil Tank | L | 900*2 | |

| Oil Tank Dimension (L x W x H) | mm | 2000 x 2500 x 550 | |

| Control Method | AC / DC (Japan SANYO) | ||

| Rated Current | A | 100 | |

| Machine Dimension (L x W x H) | mm | 2200 x 3600 x 2920 | |

| Machine Weight | kg | 5200 | |

» Current Parameters

| Max. Working Current | Best Speed / Efficiency | Best Electrode Loss | Best Surface Finishing | Input Power |

| 100A | 750 mm³/ min. | ≤0.3% | 0.2/AC | 0.3/DC | 10 KVA |

»Accuarcy | Precision (Standard:GB/T 5291.1—2001)

| Items | Resualt | |

| Flatness of the workbench | 0.03mm / 1000 | |

| X Axis Movement Straightness | in Y-X plane | 0.015/ 500 |

| in Z-X plane | 0.015 / 500 | |

| Y Axis Movement Straightness | in X-Y plane | 0.015 / 500 |

| in Z-Y plane | 0.015 / 500 | |

| Z- Axis Movement Straightness (Spindle Perpendicularity ) | move on X axis | 0.02 / 200 |

| move on Y axis | 0.02 / 200 | |

| Parallelism of work table | move on X axis | 0.015 / 300 |

| move on Y axis | 0.015 / 300 | |

| X-Y Axis Squareness | 0.015 / 500 | |

» Configuration | Setup

| Resine Sand Casting | Machine Body : HT250 |

| Work Table: HT300 | |

| X/Y Axis: | JANPAN SANYO DC/AC Servo |

| TAIWAN PMI Linear Guideway | |

| TAIWAN PMI Ball Screw | |

| Z Axis: | JANPAN SANYO DC/AC Servo |

| TAIWAN PMI or HIWIN Linear guideway & Ball screw | |

| JAPAN NSK Bearing | |

| Universal | Denmark GRUNDFOS or Taiwan WALRUS Oil Pump |

| Taiwan Automatic Fire Extinguisher | |

| Taiwan Halogen work lamp | |

| Taiwan Skeet chuck |

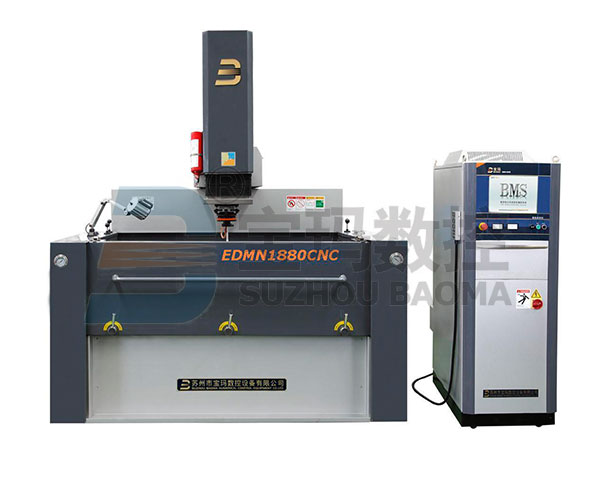

Baoma EDM machine is a precision cavity molding machines. Can make use of conductive material (such as copper, graphite, steel) as a tool electrode, the work piece (usually should be conductive material) for processing. Mainly used for precision dies, cavity mold (such as plastic mold, Bakelite mold, die casting mold, etc.), holes, Hole and other processing. Is a machine shop, mold shop ideal processing equipment.

1.Adopt Japan SANYO AC/DC servo motor or JAPAN Panasonic AC servo motor.

2.X/Y/Z Axis Adopt Taiwan Class P Line Guide way, imported double nut ball screw.

3.CNC modular structure, the system has good scalability, portability and maintainability.

4.Machine Body is resin sand, non reniun force advanced casting, Adopt HT300 ageing treatment casting, keep precision long time. Structure is reasonable, no deformation, rigid, durable, precision remains unchanged.

5.JAPAN NSK bearing, Adopt high quality imported oil pump.

6.Digital servo system Drive Three-axis, can Flexible Choose the servo strategy during machining according to the feedback signal, ensure keeping continuously, steady and high efficiency machining.

7.For copper, graphite, steel, on the cavity, and special shape holes machining

8. Lubrication system uses recovery mode, rail lubrication action at once, and keep the look clean

9.The computer is Taiwan IPC, the sub-functional modules controlled by a dedicated chip. Greatly improving the timeliness and reliability.

10.ISO-G Code Program.

Cleanliness, difficult to process conductive metal molds, complex metal parts and templates. EDM processing machinery manufacturing has become an important part in the mold, electronic equipment, precision machining, automotive parts, military and other fields have a wide range of applications.

1.Adopt Japan SANYO AC/DC servo motor or JAPAN Panasonic AC servo motor.

2.X/Y/Z Axis Adopt Taiwan Class P Line Guide way, imported double nut ball screw.

3.CNC modular structure, the system has good scalability, portability and maintainability.

4.Machine Body is resin sand, non reniun force advanced casting, Adopt HT300 ageing treatment casting, keep precision long time. Structure is reasonable, no deformation, rigid, durable, precision remains unchanged.

5.JAPAN NSK bearing, Adopt high quality imported oil pump.

6.Digital servo system Drive Three-axis, can Flexible Choose the servo strategy during machining according to the feedback signal, ensure keeping continuously, steady and high efficiency machining.

7.For copper, graphite, steel, on the cavity, and special shape holes machining

8. Lubrication system uses recovery mode, rail lubrication action at once, and keep the look clean

9.The computer is Taiwan IPC, the sub-functional modules controlled by a dedicated chip. Greatly improving the timeliness and reliability.

10.ISO-G Code Program.

intelligence operation:

1, manual feed control (MFR0-MFR3) fourth gear speed manual feed available

2, contact sensing (ST) function

3, various positioning modes to choose from

4, way mobile functionality

5, limit mobility features

6, return to the starting point processing function

7, the international standard G code programming

8, automatic positioning function

9, discharge position alignment (positioning) function

10, automatic calculation of neural network processing function (1,2,3 root electrode)

11, the function automatically calculates the processing conditions (for a given area automatically generated)

12, LORAN processing function (for a given size translational automatically generated)

13, empty running function

14, carrying knives automatic control (AJC) function

15, very inter-discharge, automatic cleaning arc processing

16, user program processing functions

17, manual processing (number of input conditions and data processing) functions

18, a single processing function of processing conditions

19, the auxiliary processing function

20, thread cutting function

21, the system automatically generates the NC program, automatic processing function (AUTO)

22, electrode switching, the electrode offset, M / T code and other direct operating functions

23, straight, circular, spiral, functional

24, the discharge diagram shows the function

25, the processing efficiency of the function display

26, the processing time counting function

28, Inch / Metric conversion function

28, self-diagnosis, help, error messages, prompts and other functions

29, time processing functions

30, to suspend processing and restore processing functions

31, off automatic reset function