| CNC Vertical Machining Center | Unit | BVMC - 650 |

| X/Y/Z axis travel | mm | 600 x 500 x 500 |

| Table upper surface to spindle nose end face | mm | 105 - 605 |

| Table to spindle nose | mm | 530 |

| Positioning Accuracy (mm) | mm | ± 0.005 |

| Repeatability Accuracy (mm) | mm | ± 0.003 |

| Spindle Speed (rpm) | mm | 8000 / 1000 / 12000 |

| Spindle bore taper | NO.40 | |

| Table dimension | mm | 800x520 |

| Max. load on table | kg | 600 |

| T shape groove | mm | 18T x P125 x 3 |

| Power (X/Y/Z) | kw | 1.2, 1.2, 1.2F Fanuc |

| 1.5, 1.5, 1.5 Mitsubishi | ||

| Rapid speed (X/Y/Z) | mm / min | 36000 |

| Cutting speed (X/Y/Z) | mm / min | 12000 |

| Tool holder model | BT40 | |

| Tool capacity | pcs | 16 |

| Tool exchange time (T-T / C-C) | sec | 7 / 13 |

| Spindle power (30min / successive) | KW | 3.7 / 5.5 Mitsubishi 5.5 / 7.5 Fanuc |

| Rated Power | KVA | 18 |

| Air power | Mpa / L / min | 0.6/200 |

| Machine height | mm | 2500 |

| Floor space | mm | 2100 x 2100 |

| Machine Weight | Kg | 5800 |

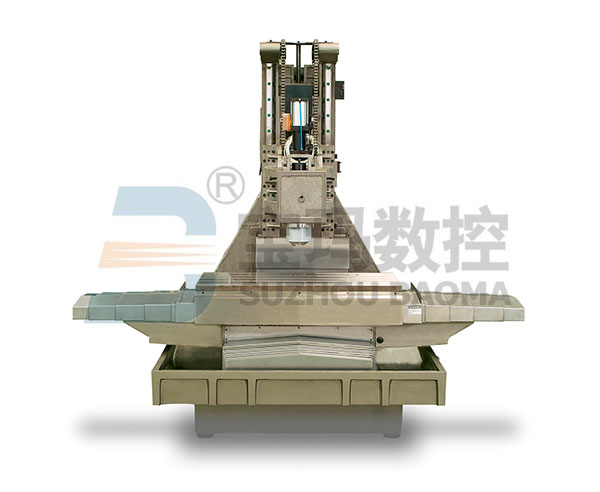

BM-VMC series CNC vertical machining center is a cooperative designed product with German company. We adopted advanced international idea of designing a modern structure machine tool and used the latest software to analyze various technical data. Most reliable and high quality components and spare parts have been introduced to this nice machine tool. No matter precise elements machining or moulds processing, BM-VMC series machining center will offer you excellent performance, high efficiency, higher accuracy and long-term stability.

Suitable for: machining parts of automobile, mold industry and so on.

The Main Features of Machine

BM-VMC series machining center will offer you excellent performance, high efficiency, higher accuracy and long-term stability. We adopted advanced international idea of designing a modern structure machine tool and used the latest software to analyze various technical data.Most reliable and high quality components and spare parts have been introduced to this nice machine tool. No matter precise elements machining or moulds processing, BM-VMC series machining center will offer you excellent service.

Mechanical Advantage - Main Machine Castings of VMC machining center are made by advanced Meehanite casting iron. Such kind of material is very stable and can make sure there is no distortion after long-term using. Grade of casting is GC -275. We adopted integrated forming technology, box structure, plus our large 5 axis machining center machine to finish processing of them by just once fixing, this characteristic makes sure good rigidity, high intensity excellent geometrical precision of VMC machines. At the same time it promises long term stability and accuracy. Other companies choose normal casting and steel plates welding method to produce machine bed parts; these machines are bad in performance, easy to happen resonance, easy to break down, short life, can’t do heavy cutting work, will lead to great loss. |

|

| Use of Mechanite Cast Iron GC40 (GC275) Mechanite cast iron GC40 is suitable for casting with thickness 10-15mm. This kind casting is good in compact structure, good intensity, suitable hardness, low coefficient of friction, it has feature of self-lubricating, after quenching treatment, and it is widely used as workpiece which have friction of its surface, such as machine tools bed, seat, working table, and cylinder, and so on. |

Mechanical Advantage -“人” Structure Column “人” structure is adopted as column to support spindle box and its movement in Z axis direction, Using such design can improve rigidity and cutting stability of machining remarkably, with this design, our machine is suitable for heavy cutting and large table load. |

|

| Mechanical Advantage - unique tool changing structure A: Special material as this structure, processed by precious machining and unique heat treatment, accelerates changing tools; this design is much accurate (no impaction to spindle) and smooth without noise. B: We adopt particular, stable air pressure driving oil as method of spindle loosing tools, double-action, it is much excellent in speed and stability of than just using air pressure or oil driving. C: Large capacity tool magazine with 24 tools, advanced cam type tools changing system is equipped, random memory of magazine management, which much faster and stable in changing tools. (Optional) |

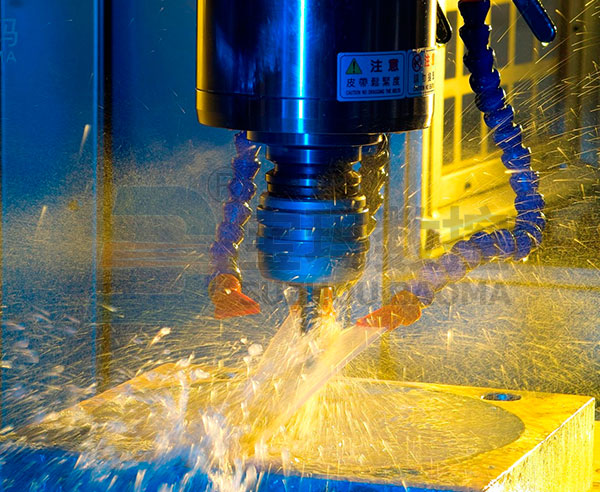

Mechanical advantage - high Precious, High Rigid Spindle

Spindle of our VMC machine are made by top brand in TAIWAI. The range of spindle speed is 8000-12000. Spindle taper is No. 40, which strengthen of cutting power. Belt transmission can reduce slip; noise caused by transmission and hears generation. We use high- power motor for spindle and other three axes. High width torque outputting, even working with slow speed, it can output high torque. This is suitable for heavy cutting work.

Mechanical Advantage - Precious Ball Screw

Screws of X, Y, Z axes are provided by worldwide famous manufacturer, such as HIWIN, PMI in Taiwan, specification of screw: P3 precious level, diameter is 40mm, guide lead 12mm. Such kind screws are leading in speed and accuracy. As to support of screw, we used fixed support with pretension, which enhance transmission. Bearing for holding up screws are made by NSK in Japan, NSK bearing have much better performance than others in many aspects, such as loading, rigidity, motility. Coupling, which is used for connecting screw and motor are American plum blossom-sharp. This structure is characterized in high efficiency, good rigidity, transferring with big torque, turning with high efficiency, but small self-running inertia, it is suitable for high speed working.

Mechanical Advantage - Optimized Structure of Heavy Rail Linear Guide

Roller guide (Standard)or ball screw guide (Optional) for X,Y,Z axis of Baoma machines, which is provided by worldwide well know enterprises. Comparing with ball screw guide, leading and damping properties of roller guide has been improved 30% and 15% respectively, comparing with steel guide, dynamic motion function has been improved 300%, at the same condition, machining efficiency will be 2-15% better, lift of machine will be 3-6 times longer, so no need to break machine own to repair, it will save production cost.

Mechanical Advantage - Adopt Three Slide Blocks for Spindle Axes

Adopting three slide blocks for single axis will enhance load capacity around 30% ,with this method the load capacity and the rigidity will be improved.

Mechanical Advantage - Nut Integrated Design

Nut block for screw and main machine body are built together for every axis, with this design, machine will get better rigidity and won’t lost accuracy while heavy cutting with acceleration movement impact.

Friendly use operation interface, Excellent looking of outside cover

Oil and water separated design keep working solution away from lubricating oil. Excellent chip cleaner (optional) Safe and convenient operation platform.

▲:Optional function ●:Standard Function [Mitsubishi System]

1.CPU and control axes

▲ 1.1 64 bit CPU

▲ 1.2 Max. Number of Control Axes (NC+SP+PLC+external axes):11

▲ 1.3 Max Number of spindle: 2

▲ 1.4 Max number of NC axes: 6

● 1.5 Number of coincidence acting axes: 4

2.Corrections associated with the memory capacity

● 2.1 Standard capacity of machining program memory /number of program: 600meters/400

● 2.2 Max number of common variable group: 600

● 2.3 Max number of tool compensation group: standard 400

● 2.4 Max number of coordinate extension: 54 groups

3.Machining speed and precision support method

▲ 3.1 High speed machining mode Ⅲ:G05P3 (16.8m above)

● 3.2 High Accuracy control 1: G61.1 (8.4m/min)

● 3.3 High speed and high accuracy modeⅠ (G5.1Q1):G5.1Q1 (16.8m/min)

● 3.4 High speed and high accuracy model Ⅱ(G5P10000):G5P10000 (33m/min)

4.Special edit mode

● 4.1 buffer emendation (memory/MDI/Computer Link B)

▲ 4.2 buffer emendation (HPS)

● 4.3 whole page edit/whole sentence edit

5.Display real time connect with computer

● 5.1 display: 8 inch CRT (amber)

▲ 5.2 display-optional: 8.4’’ TFT-LCD

▲ 5.3 IC card high speed program server + Ethernet (HPS): HR831 + HR832 + IC Card

● 5.4 Computer online B (Max pre-read capacity is 32KB, about 500 units/time): 32KB/500B, Transfer Rate: 38400bps

▲ 5.5 Ethernet (10/100Mbps) HR831 + HR832

6.Language and Graph

● 6.1 support language (Japanese, English, Chinese, French, Spansh….): 13 countries (including simplified Chinese)

● 6.2 PCL grogram wire-protected

● 6.3 graph simulation

● 6.4 tool path check

● 6.5 Zoom in and zoom out of graph, center keep

7.Operation and ability of program support

● 7.1 Measure center of wrokpiece: B3A version

● 7.2 Ability of automatic input for compute, and measure of workpiece coordinate compensation

● 7.3 Restart program

● 7.4 Exchange of coordinate display value

● 7.5 Check halt

● 7.6 Round milling

● 7.7 Compensation of workpiece position

● 7.8 Program coordinate turn around

● 7.9 Peck synchronism tapping/deep hole tapping (can trace back to R point)

● 7.a Proportion zoom (G50/G51): B3A version

● 7.b Parameters mirror

● 7.c External mirror

● 7.d Program mirror

● 7.e Special regular recycle program(G34/35/36/37.1)

8.Interpolation ability

● 8.1 Polar coordinate command (G15/16)

● 8.2 Cylinder interpolation (G07.1)

● 8.3 Threading interpolation (G17 -19 + G02/G03)

9.Maintenance ability and others

● 9.1 Parameters backup

● 9.2 Waveform display

▲ 9.3 Easy program interface: Magicpro-NAVI MIL

▲ 9.4 APLC (open user interface): APLC

▲ 9.5 UI of PC version: PRO-CAM/M

▲ 9.6 MEL Link (1 to 5 DNC S/W software): MEL LINK

▲ 9.7 M70S series: operation, program alarm/parameters electric book